Introduction Video for Injection Molding Machine

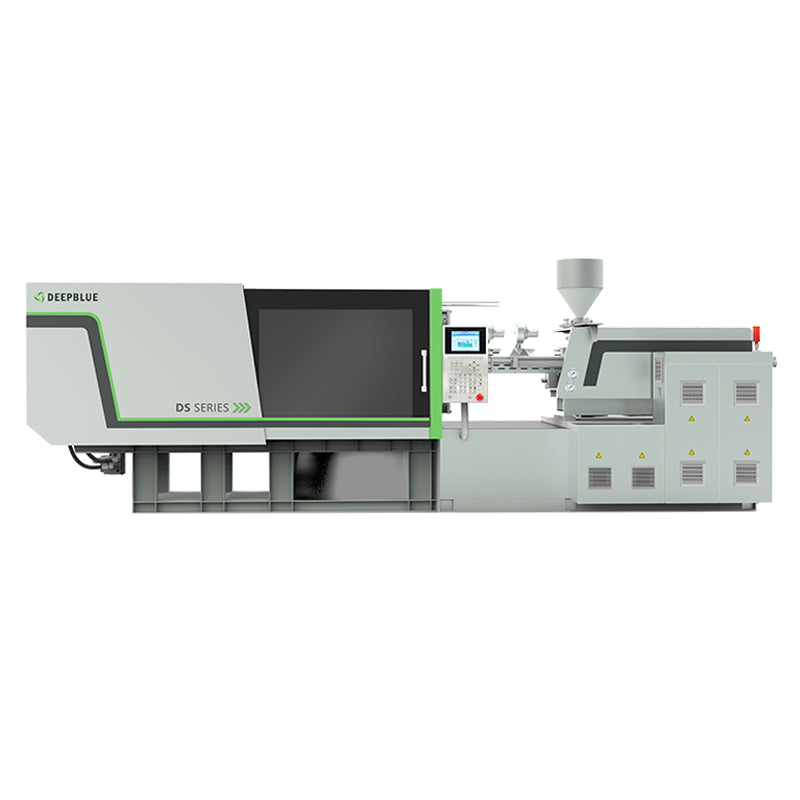

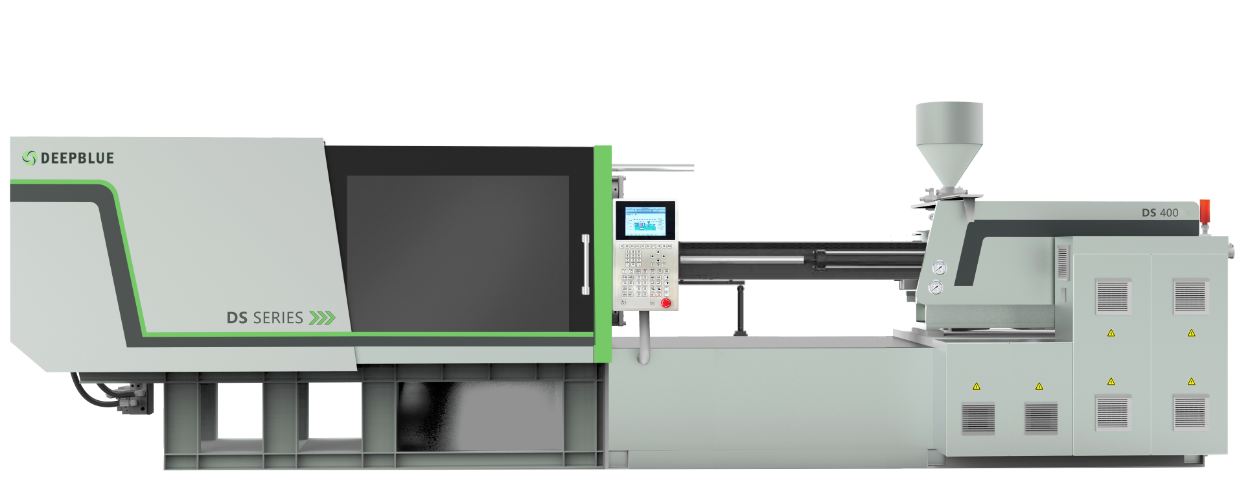

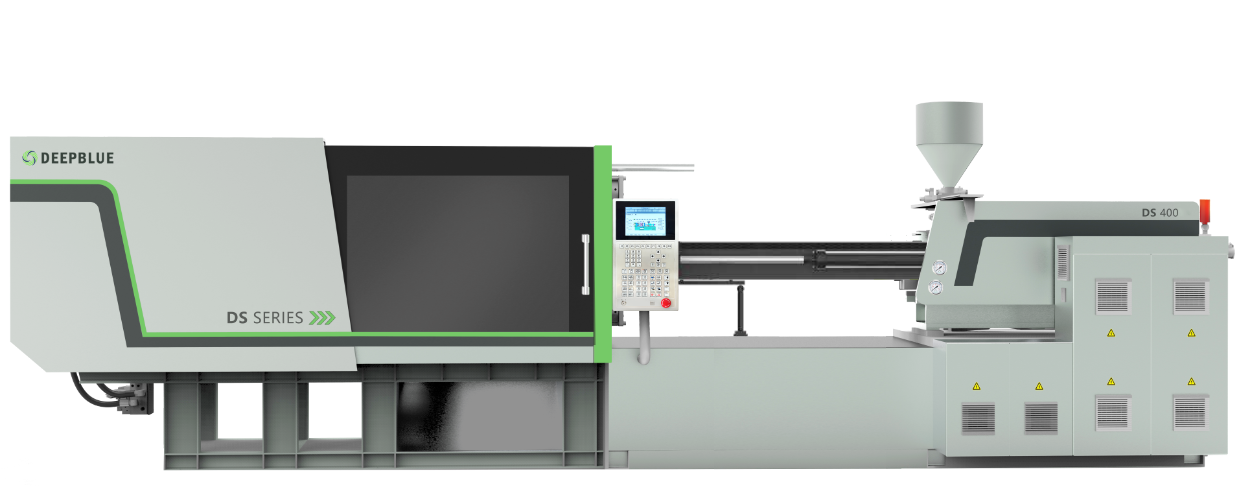

Servo-Hydraulic Injection Molding Machines: Pricing and Features

Optimize Costs with Our High-Performance Servo-Hydraulic Injection Molding Machines.

Our Features

-

Precise and stable

Deepblue Smart Equipment's machines deliver exceptional accuracy and consistent performance, ensuring high-quality production. Engineered for reliability and efficiency, our solutions minimize downtime and optimize productivity, maintaining uniformity and precision across all production runs.

-

High-efficiency and energy-saving

Deepblue Smart Equipment's machines optimize production with high efficiency and reduce energy consumption, delivering sustainable, cost-effective solutions that enhance productivity and support environmental responsibility.

-

Wide range of application

Deepblue Smart Equipment's robust machines are versatile, suitable for various industries and applications, ensuring reliable performance and adaptability to diverse manufacturing needs.

Collection: PET preform injection moulding machine

Deepblue Smart Equipment

60ton - 250ton Injection Molding Machines

Share

Deepblue Smart Equipment

300ton-600ton Injection Molding Machine

Share

Deepblue Smart Equipment

PET injection moulding machine

Share

Deepblue Smart Equipment

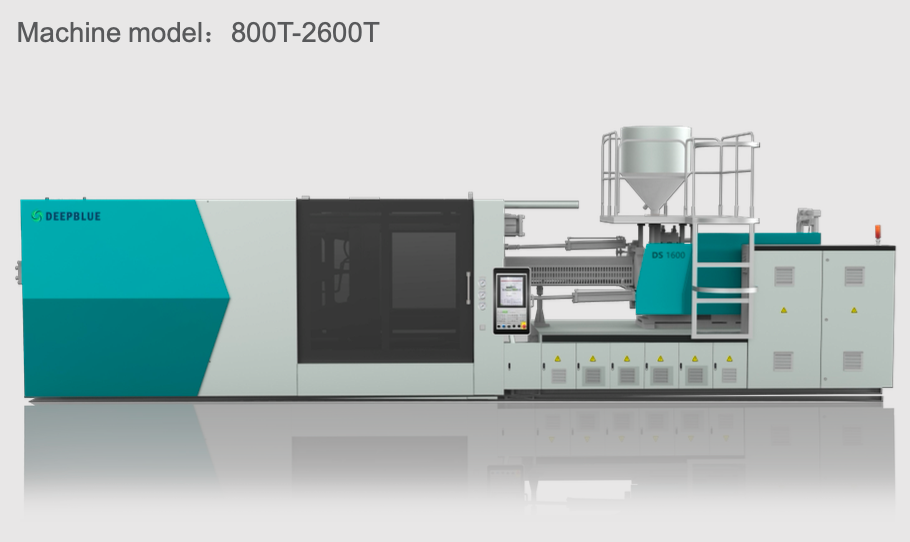

800tons -2600tons Injection Molding Machine

Share

Used Injection Molding Machine

Discover cost-effective, reliable used injection molding machines at Deepblue Smart Equipments. Save on high-quality equipment with immediate availability, proven performance, and expert support. Choose from top brands and enjoy flexible financing. Enhance your production sustainably and efficiently.

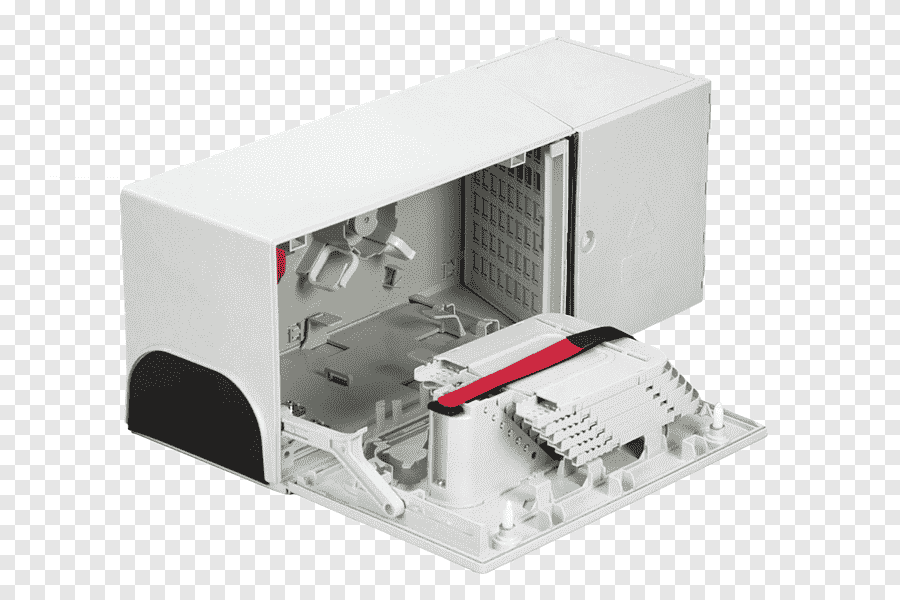

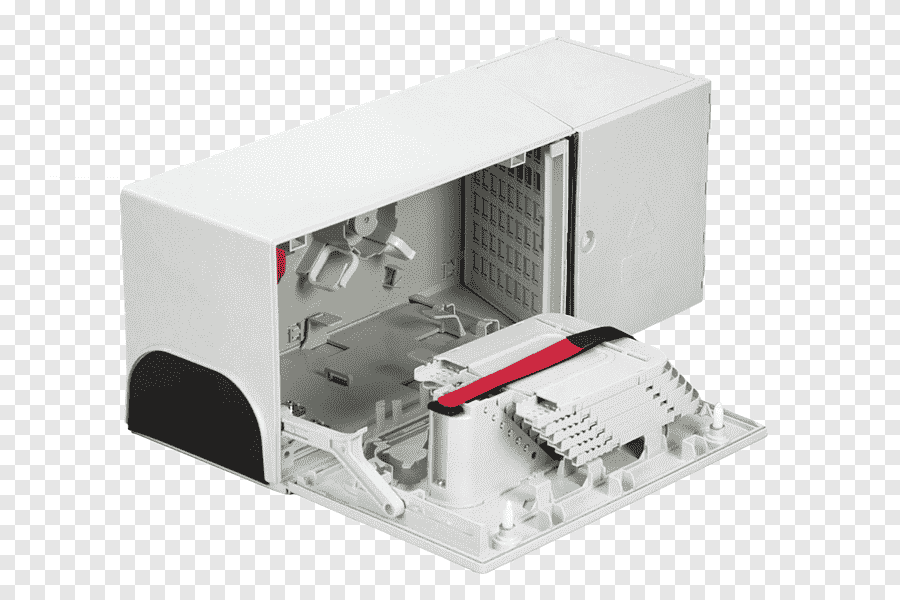

Key Components for Injection molder

At Deepblue Smart Equipment, we pride ourselves on providing top-of-the-line KEY Components that enhances the performance, reliability, and efficiency of our injection molding machines.

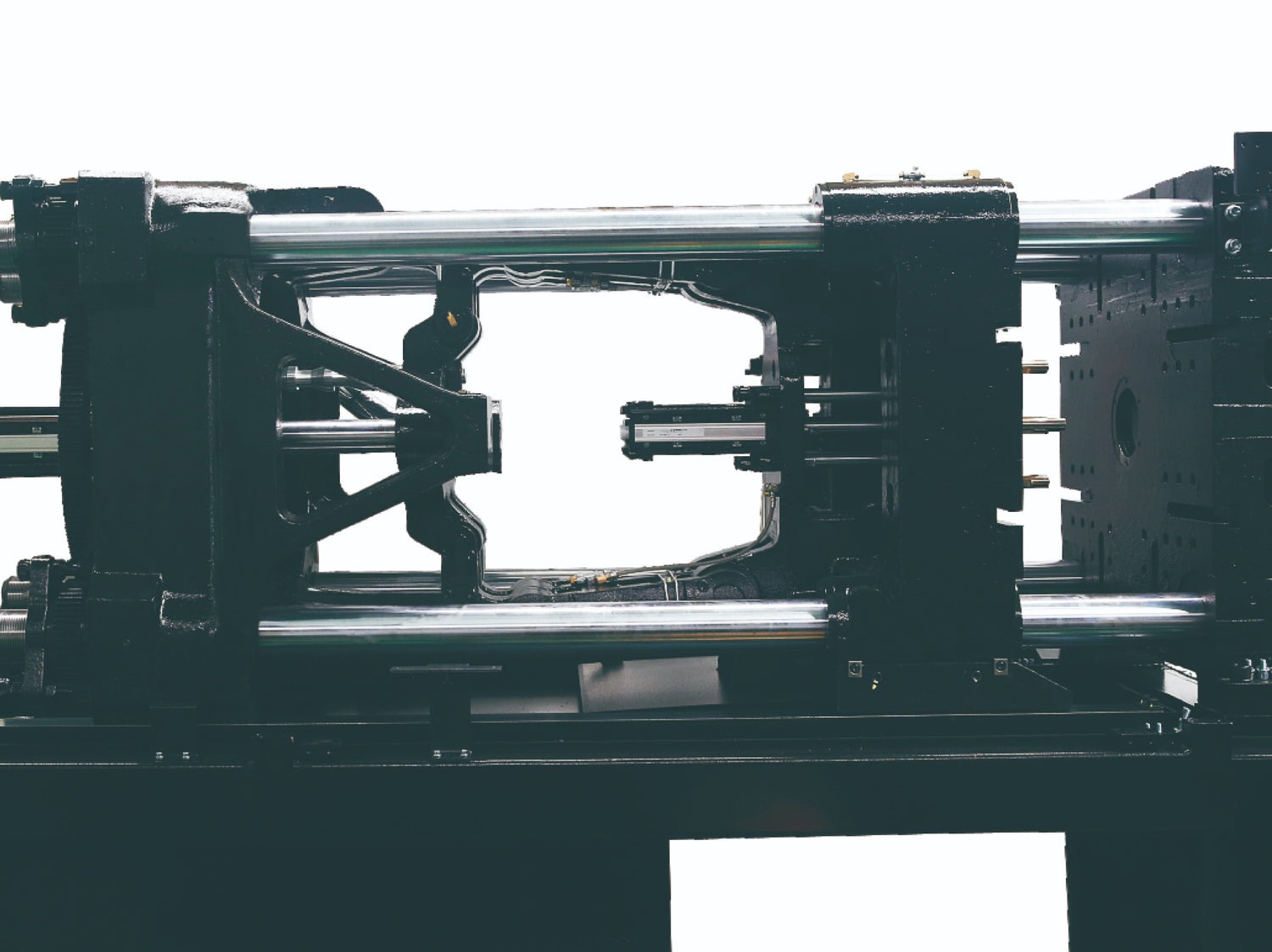

Clamping Unit

Improves the rigidity of clamping unit by 30%, enhances installation and removal of mold, decreases thread wear from screw hole use, and extends platen lifespan.

Injection Unit

- Optimized injection structure design improves rigidity of injection unit;

- Reduce all frictional resistance during injection molding process enhance the stability & precision of injection.

New-generation servo system

With years of market validation, we offer features such as better combined configuration, robust and reliable system performance, high energy efficiency, low-noise, strong power, and fast response.

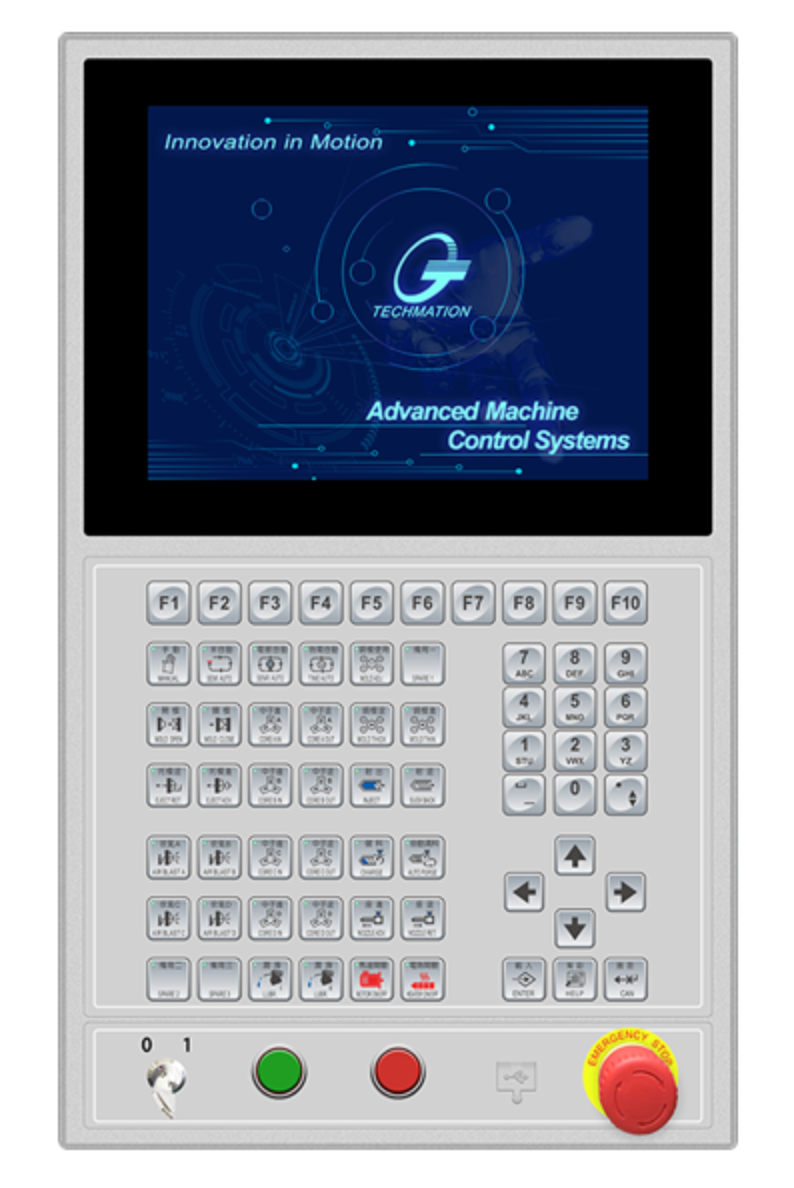

High-precision control system

-Real-time monitoring of signals from machine equipped sensors to coordinate corresponding movements for higher operating safety;

- Support common RS232/485 communication interface, CANOPEN, Ethernet, temperature compensation sensor, and USB port.

Industries for plastic Injection molding machines

Plastic injection molding machines are widely used across various industries due to their versatility, precision, and efficiency in producing high-quality plastic parts. Here are some of the key industries that rely on plastic injection molding machines

Industries

-

AUTOMOTIVE INDUSTRY

The automotive industry has a wide range of applications, from visible interior parts to precision exterior components like bumpers and cockpits. Different production solutions are needed to meet various requirements for material homogeneity and precision.

-

WHITE GOODS INDUSTRY

White goods are essential technical achievements for private households, ranging from large appliances like washing machines and refrigerators to small ones like coffee machines and mixers. The production of components for these appliances varies greatly in size and requirements for appearance and material quality.

-

ELECTRONICS INDUSTRY

Products for electronics market are wonders of technology with minimalist designs and mega functions, requiring a comprehensive quality approach due to hot competition.

-

CONSUMER GOODS INDUSTRY

Plastic injection molding technology has made consumer goods more affordable and diverse, from shirt buttons to toolboxes.

-

LOGISTICS INDUSTRY

In the logistics market, robust transport is crucial for plastics processing. This includes containers, barrels, drums, boxes, crates, plastic pallets, and bottle trays. They need to be lightweight for low transport costs, with high stability and resistance to environmental factors.

-

TOY INDUSTRY

Plastic injection molding technology has made toys more affordable and diverse, from lego toys to many other toys. The process has revolutionized the toy industry by enabling mass production at a lower cost.

Other Industries

Aerospace Industry

Applications: Manufacturing of lightweight components such as interior panels, brackets, housings, and ducting systems for aircraft.

Benefits: High strength-to-weight ratio of plastic parts and the ability to meet stringent quality and safety standards in aerospace applications.

Construction Industry

Applications: Production of building materials such as plastic fittings, piping systems, wall panels, roofing sheets, and insulation components.

Benefits: Durable, weather-resistant plastic parts that can withstand harsh environmental conditions, providing long-lasting construction solutions.

Agricultural Industry

Applications: Manufacturing of irrigation components, greenhouse accessories, planters, seed trays, and other agricultural tools.

Benefits: Durable and cost-effective production of specialized plastic parts that improve efficiency and productivity in farming.f

Sports and Leisure Industry

Applications: Manufacturing of sports equipment, protective gear, recreational products, and toys.

Benefits: Flexibility in design and ability to produce lightweight, durable, and ergonomically designed products for enhanced user experience.

Home Appliances Industry

Applications: Production of plastic components for kitchen appliances, air conditioners, washing machines, refrigerators, and vacuum cleaners.

Benefits: Cost-effective production of durable, high-quality parts that withstand daily use and harsh conditions.

Furniture Industry

Applications: Manufacturing of plastic components and accessories such as chair bases, armrests, handles, and decorative elements.

Benefits: Customizable and cost-effective production that meets the aesthetic and functional requirements of modern furniture design.

Request a Quote for Your Injection Molding Solution!

Fill out the form below, and our team will get back to you with a tailored quote and expert advice to meet your production needs.

By submitting this form, you agree to be contacted by our sales team to discuss your requirements further. We are committed to protecting your privacy and ensuring your information is secure.